Welding vs. Spinning vs. Stamping: Which Process Is Right for Your Part?

When you’re designing a metal component, one of the first decisions you’ll face is how it should be formed, and rightly so. After all, the process affects everything, from performance and appearance to production cost and turnaround time.

We work with engineers every day who are weighing up these trade-offs. Let’s look at welding, metal spinning, and metal stamping, and how to determine which of these processes best suits your application.

Welding

Welding joins separate metal pieces into a single, unified structure. It’s often the first forming approach engineers consider because of its flexibility during design changes and early prototyping.

When Welding Makes Sense

Welding works best when the geometry of your part is complex or difficult to form from one piece. It’s equally valuable in the early stages of product development when designs are still evolving.

- Prototyping and Low-Volume Runs: Welding minimizes up-front costs because there’s no need for dies or large tooling investments.

- Complex Assemblies: Multi-part designs or varied thicknesses can be joined precisely without compromising strength.

- Maintenance and Repair: Welded joints extend part life by reinforcing stress points or replacing worn components.

Limitations

Because welding introduces heat, thin materials can distort without proper fixturing or control. It also becomes less cost-efficient as production volumes grow, where automation and repeatability matter more.

In these cases, we often guide customers toward spinning or stamping once designs stabilize.

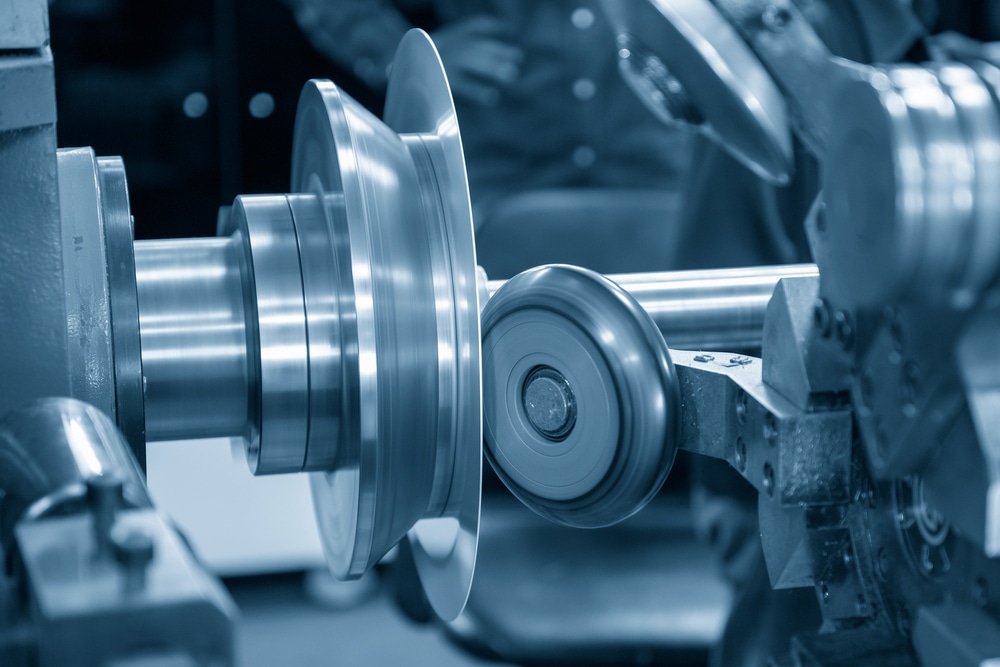

Metal Spinning

Metal spinning transforms a flat metal disc into a round or conical shape using a rotating mandrel. It’s one of the oldest forming processes, and one that continues to outperform for circular parts.

Why Engineers Choose Spinning

If your design revolves around symmetry, spinning can offer remarkable precision and strength. The process compresses and stretches the metal’s grain structure rather than cutting or welding it.

- Superior Structural Integrity: The material’s grain remains continuous, resulting in stronger, more uniform walls.

- Material Efficiency: Because spinning forms rather than removes material, scrap is minimal.

- Fast Design Iterations: Adjusting mandrel geometry or tooling allows quick prototype changes without major expense.

Ideal Applications

You’ll see spun parts in aerospace housings, lighting reflectors, defense components, and HVAC cones. In short, think of anywhere you need consistent, circular geometry.

If you’re considering casting or machining for a similar part, spinning often achieves the same result faster and at lower cost.

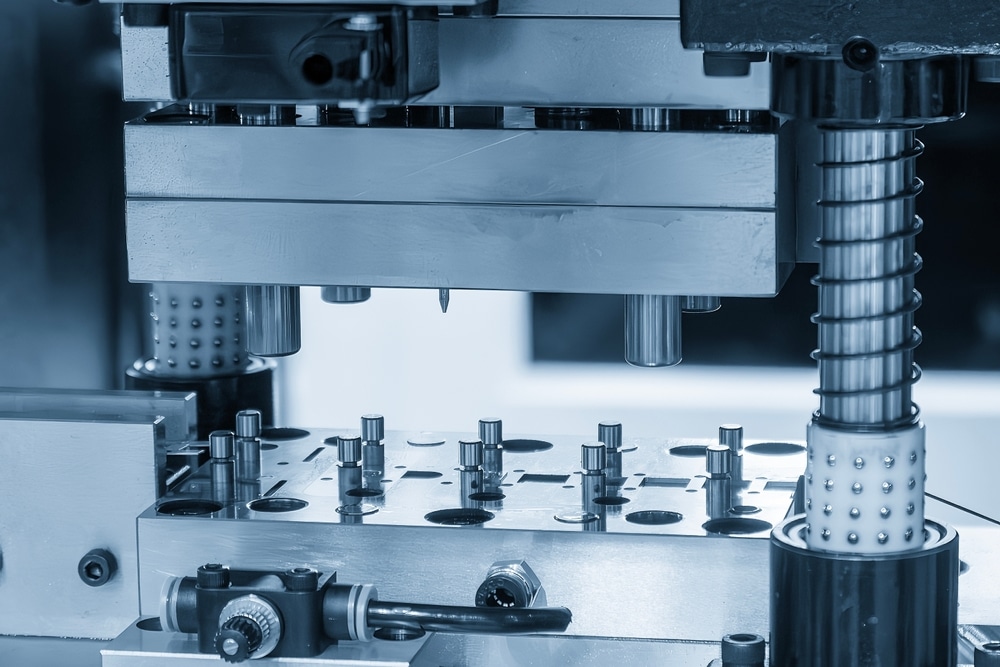

Metal Stamping

Stamping uses a press and die set to shape sheet metal at high speed and precision. Once the tooling is complete, it becomes the most efficient option for high-volume production.

Where Stamping Excels

Stamping is the go-to process when consistency, scale, and cost-per-part are critical. Once the dies are dialed in, output is predictable and repeatable.

- High Production Volumes: Ideal for thousands (or millions) of identical components.

- Tight Tolerances: Controlled die geometry ensures every piece matches design specifications.

- Speed and Automation: Progressive dies combine multiple forming operations in a single press cycle, reducing labor and lead times.

Factors to Consider

Tooling costs for stamping can be significant, so it’s best suited for mature designs where you can amortize those expenses across large runs.

However, with TSM’s in-house design and engineering team, we help customers transition from welded prototypes to stamped production seamlessly.

Comparing Processes for Design Efficiency

Every forming method has something to bring to the table. For instance, welding gives you flexibility when geometry or assembly changes are likely.

Meanwhile, spinning delivers strength and material efficiency for circular parts. Stamping drives cost efficiency as production volumes scale.

When we review drawings, we start with your design intent, from the desired shape, load, and performance expectations. We then match it to the right process.

A prototype might begin welded, evolve into a spun form for production, and eventually move into stamping as demand increases. The key is choosing a method that supports your product’s lifecycle without over-investing in tooling too early.

Choosing the Right Partner

Selecting the best forming process is also about expertise. At TSM, our engineers bring decades of combined experience in metal spinning, welding, stamping, and precision laser cutting. Because all these capabilities exist under one roof, we can assess manufacturability from multiple angles before production even begins.

Our goal is simple: To help you produce reliable, cost-efficient parts without compromising design integrity.

Explore the Right Process for Your Use Case

If you’re still deciding which process suits your part, reach out before committing to tooling or material orders. We can evaluate your drawings, advise on formability, and even prototype multiple methods to compare performance. Whether you need a single prototype or a full production run, we’ll help you move from concept to finished part with confidence.

Contact us today to discuss your project and see how TSM’s integrated capabilities can streamline your next build.

Request a Quote to Get Started

From research and development to final production, Tallmadge Spinning & Metal is your partner for cost-effective and superior metal products. Request a quote today to get started.

REQUEST A QUOTE TODAY TO GET STARTED