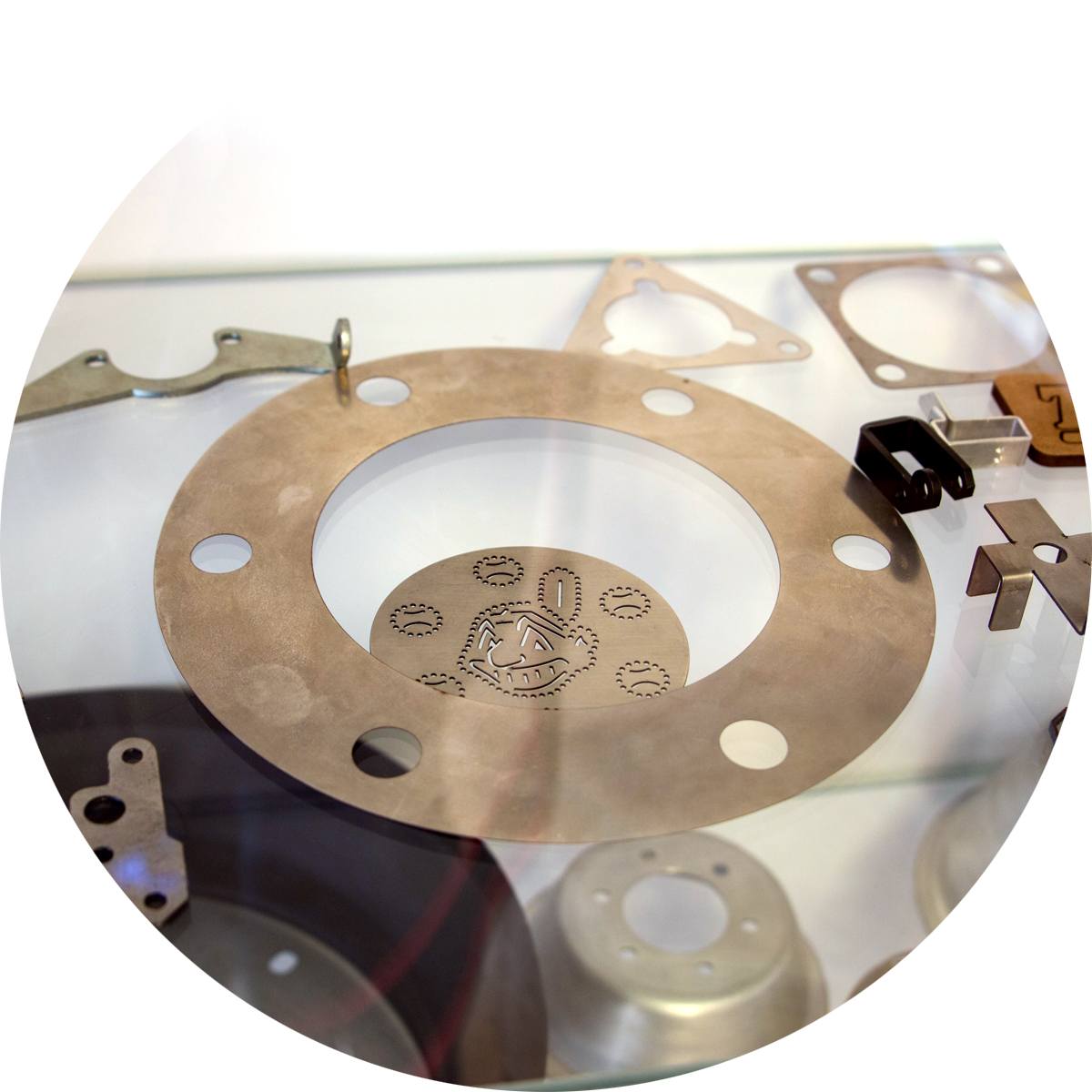

Metal Stamping Services

For producing certain types of parts in higher volumes, metal stamping can be more effective. While the upfront price to create the die is higher, the individual part cost is significantly lower than with any other manufacturing method. Metal stamping offers:

- Lower per piece price on high quantity orders

- Quicker production times once die is created

- Ability to stamp same materials that we can spin

Prototype to Production

At Tallmadge Spinning & Metal, we can help you determine what production method will be most effective for your part.

For prototypes and small volume projects we typically recommend metal spinning or laser cutting. But when your prototype is perfected and ready to go into production in high quantities, we can move to metal stamping to manufacture your part more cost effectively.

Lower Costs for High Quantities of Metal Parts

If you need a couple hundred pieces, spinning is the best choice. But once you move into the thousands, metal stamping is typically preferred.

For highly specific applications, however, metal stamping will produce a better part and is the smart choice at any quantity. We can handle those runs, as well. If you aren’t sure what you need, send us a drawing and our engineering partners can help determine how to best manufacture your part.

Quality Control Manager Oversees Production

In our dedication to quality control, we employ an in-house, full-time quality control manager to tighten our tolerances for metal stamping and other services. This manager ensures proper inspections are regularly completed and that documented processing steps are followed – every time, every job.

Request a Quote to Get Started

For parts that require metal stamping, Tallmadge Spinning & Metal is your partner for cost-effective and superior manufactured products.

Request a Quote Today to Get Started