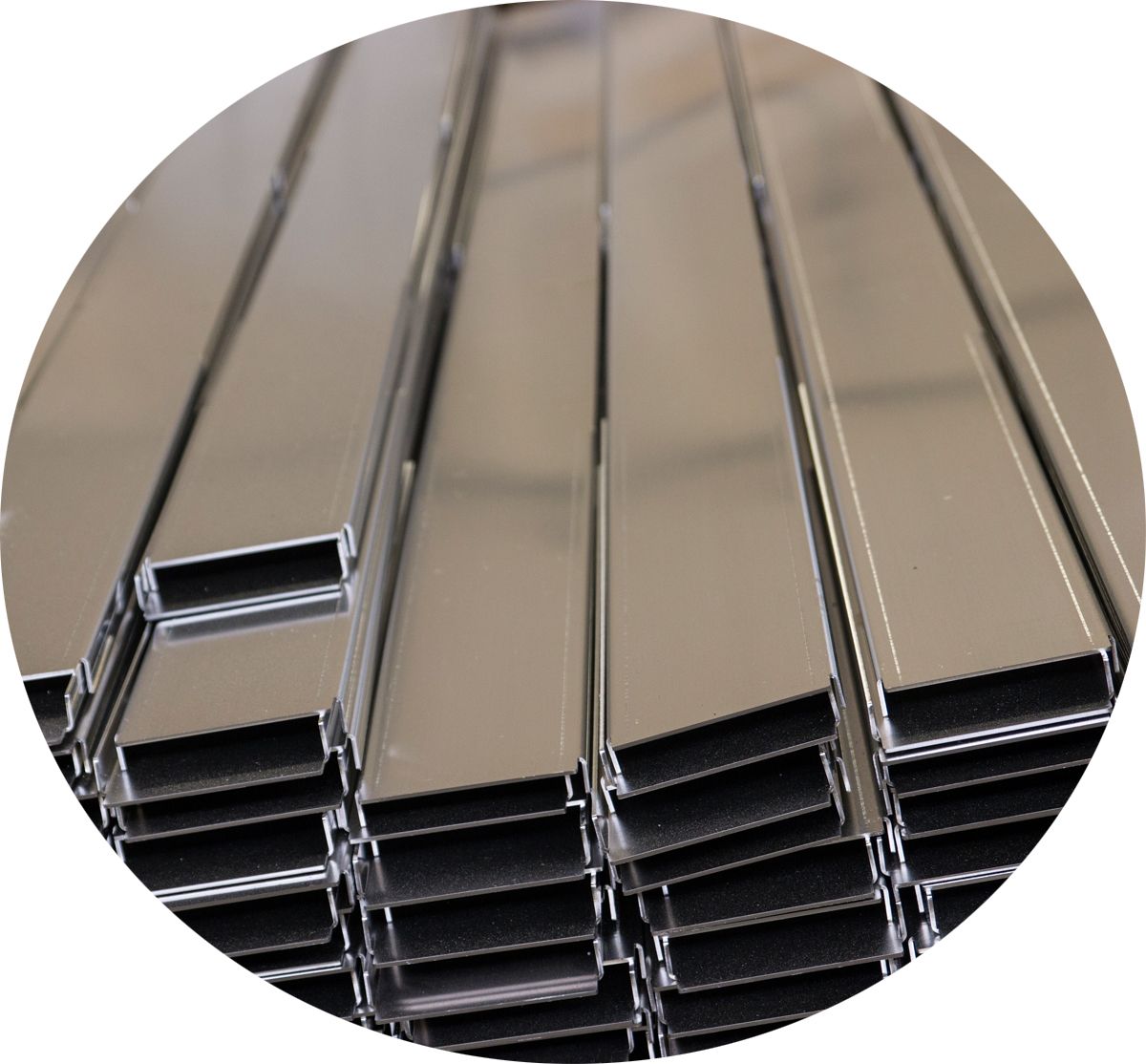

Metal Fabrication

Choose Tallmadge Spinning & Metal for any job that requires metal fabrication for cutting, bending and assembling parts. We take pride in our ability to offer:

- Wide range of high quality machinery

- Custom dies and machines for unique applications

- Start-to-finish manufacturing capabilities, rarely relying on subcontractors

- Increased quality

- Faster turnaround times

Value-Added Fabrication Shop for Finished Goods

Our fabrication shop is uniquely designed to move raw materials in and finished goods out. We are able to handle any aspect of your job and rarely need to rely on subcontractors to finish a project. Our ability to maintain total control of your project delivers increased quality and decreased turnaround times.

Metal Fabrication Experience and Expertise

Tallmadge Spinning & Metal is a three-generation family-owned business with seven decades in the metal manufacturing industry. We have years of experience in metal fabrication, along with quality equipment, that enables us to deliver quality parts well within your guidelines and requirements.

Metal Fabrication Equipment and Capabilities

Along with this machinery listed, we can make specific dies and machines to fit unique applications.

Cincinnati 6’ CBII60 hydraulic press brake

- CNC programmable ram and backstop that accommodates a wide array of bends

- Ability to store programs that cuts set-up time

- 60 ton capacity

- Can hold tight tolerances (+- .005”) on just about any type of bend.

- European style tooling ideal for complex bend profiles

Cincinnati 10’ mechanical shear

¼” mild steel capacity.

1ea. 1 ton Gantry Crane for material handling on laser tables

4ea. 1 ton jib cranes

Can reach fab tables and all three laser tables.

10’ Cincinnati Proform

- 175 Ton Capacity

- Fully CNC Controlled

10’ Cincinnati ProForm + press brake

- 135 ton capacity

- Fully CNC controlled with 5 axis back gage

- Allows the ability for extremely quick set-up between jobs

Numerous drill presses and tap machines

Tig welders

Can weld .005” up to 1 inch thick stainless and alum.

- Lincoln 300 amp

- 2ea. Miller Dynasty 200DX inverter 200 amp

Mig welders

Can weld 20 ga. up to 2 inches thick mild steel and stainless steel.

- Lincoln 400 amp welder (can run .06” flux core for a wide range of heavy materials)

- Miller 400 amp welder (can run .06” flux core for a wide range of heavy materials)

- Miller 350 amp welder with push/pull gun for excellent production work on aluminum.

- Lincoln 350 amp welder with push/pull gun for excellent production work on aluminum.

Rolling machines

- 8’ 1/8”capacity mechanical electric rolls

- 6’ ¼” capacity mechanical electric rolls

- 5’, 11ga. capacity mechanical electric rolls

- 2 small capacity hand rolls

Bridgeport style milling machine

With 2 manual turning lathes for small production machining and specialty tooling.

Clark lift truck

4500# lift capacity at full boom extension.

Request a Quote to Get Started

For parts that require metal fabrication, Tallmadge Spinning & Metal is your partner for cost-effective and superior manufactured products.

Request a quote today to get started